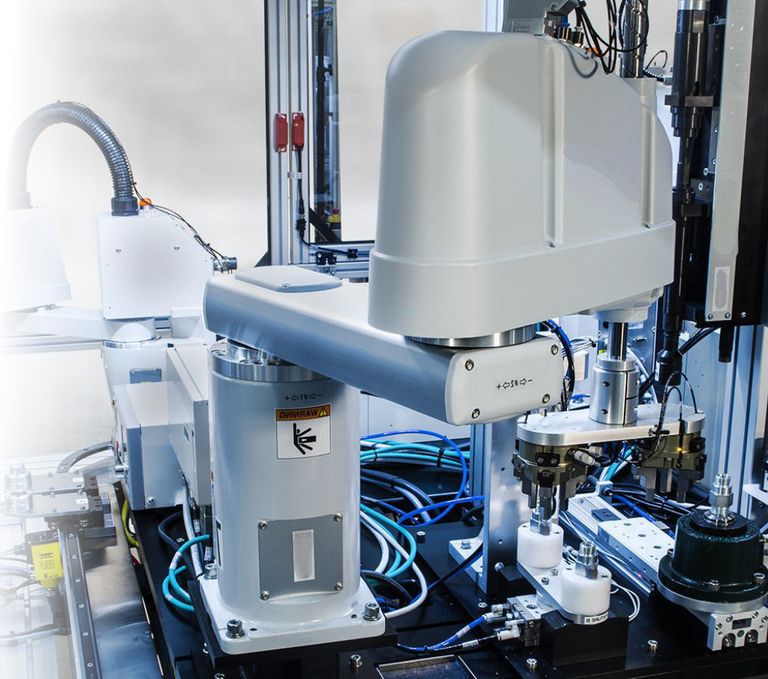

With minimal effort your hardware is connected to drag&bot OS

drag&bot OS supports a wide range of different robots, almost all grippers and material feeding systems, as well as the most common vision systems and communication interfaces.

Save valuable time when integrating grippers, cameras or PLC systems. With minimal effort, your hardware is connected to drag&bot and you can start immediately.

Use the hardware that best fits your application!

Robots

| Robot manufacturer | Controller & Software-Versions | Required software packages from the robot manufacturer |

|---|---|---|

| ABB | IRC5,IRC5 Compact, Omnicore | 616-1 PC Interface 623-1 Multitasking |

| Fanuc | R-30iB Mate & Plus > V8.10 (not V8.33) | R648 User Socket Msg R632 KAREL |

| KUKA | KR C4 iiwa | RSI > 3.1.6 Sunrise > 1.13 |

| Yaskawa | YRC1000 | MotoPlus |

| Stäubli | CS9 | - |

| Nachi | CFD >4.72 | - |

| Comau | KEBA KeMotion | See Kemro X Licences |

| Epson | SPEL 7.0+ | - |

| Denso | RC8: VS087 | b-CAP (Teil von ORiN2 SDK) |

| Mecademic | Meca500 R3 | - |

| Universal Robots | CB2, CB3, e-series | - |

Gripper

drag&bot OS supports a variety of different grippers and gripper systems from different manufacturers:

Zimmer

Zimmer Group supplies ready-to-install clamping grippers as well as customized robot solutions for gripping and positioning. All grippers based on IO are supported. For grippers that use the IO-Link protocol, an IO-Link master adapter is also required.

Schmalz

Market leader in automation with vacuum. All IO-based gripper systems are supported, e.g. the ECBPi or FXCB series.

Schunk

Schunk is the world's No. 1 for industrial gripping systems. All IO grippers as well as all grippers of the WSG series are supported.

Robotiq

Robotiq offers various grippers, vision systems and sensors for cobots. In addition to the IO grippers, the Modbus-based models 2F-85 and 2F-140 are also supported.

Weiss Robotics

Weiss Robotics offers digital clamping grippers and UR+ certified gripping solutions, among others. The manufacturer's WSG models are supported.

Camera systems

drag&bot OS supports a number of different 2D and 3D image processing systems:

Basler

Basler offers a wide range of affordable USB and network cameras and accessories for the industry.

Balluff

Balluf's Smart Vision smartcams are particularly suitable for rapid use in defect detection and quality inspection.

Cognex

Cognex's Insight smartcams cover a wide range of applications and are available with comprehensive accessories (lenses, lights, etc.).

Roboception

Roboception offers affordable 3D smartcams and software modules for specific applications in industrial automation.

Interfaces

The drag&bot OS software is alternatively available as a module in Kemro X - the modular control platform from KEBA. The combination of Kemro X and drag&bot OS results in further advantages. For example, the following functions can be used together with drag&bot OS on a KEBA control:

Individual machine visualization

Using KEBA's own visualization framework, machine builders can quickly and efficiently create their own graphical user interfaces.

Own robot control

KeMotion, the robot control software from KEBA is compatible with drag&bot OS and can be used together.

Interfaces & Hardware Modules

Kemro X has its own EtherCAT master and also supports other industrial protocols. In addition, various interfaces are available.

Integrated SPS

Kemro X uses CODESYS for SPS programming for industrial control and automation technology.

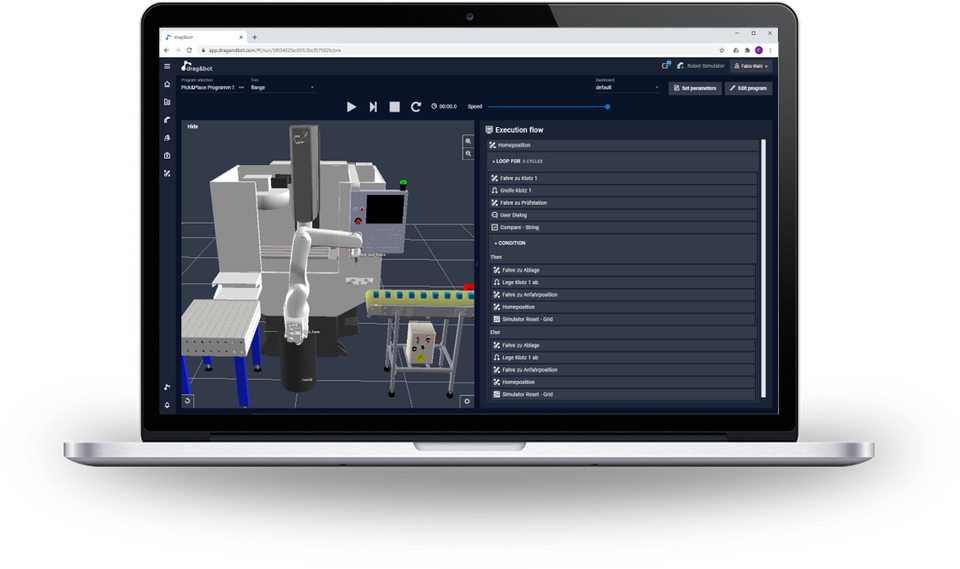

drag&bot SIMULATION

Try out the software yourself

drag&bot SIMULATION is the test version of dra&bot OS that works completely in your browser or in the cloud (without real robot hardware). Sign up right now to get to know our software - and receive your personal access data directly via email so you can get started right away.