Changing market conditions pose significant challenges for companies

Increasing product variations and shorter product life cycles increase the need for flexibility, adaptability and speed

The changed market conditions can also be felt in robot automation: more and more experts who can set up and program robot systems are missing. Due to increasing product variants and ever shorter product life cycles, the desire for more flexibility and fast adaptability of robot applications in machines and plants increases.

- Lack of expertise

- Self-developed solutions require a lot of time and money

- Different robot brands increase integration efforts

- Complex retrofitting of automation solutions

Advantages for solution providers

Opening up new markets

Tap into a market segment that was previously unaddressable: Customers with high demands on the flexibility and usability of the system.

Reduce time and costs

Benefit from available visualization and integration solutions instead of reinventing the wheel:

- Reduce development effort

- Reduce time to market

Stay independent

Same appearance of the user interface - regardless of the robot brand.

Less integration effort when using a new robot brand.

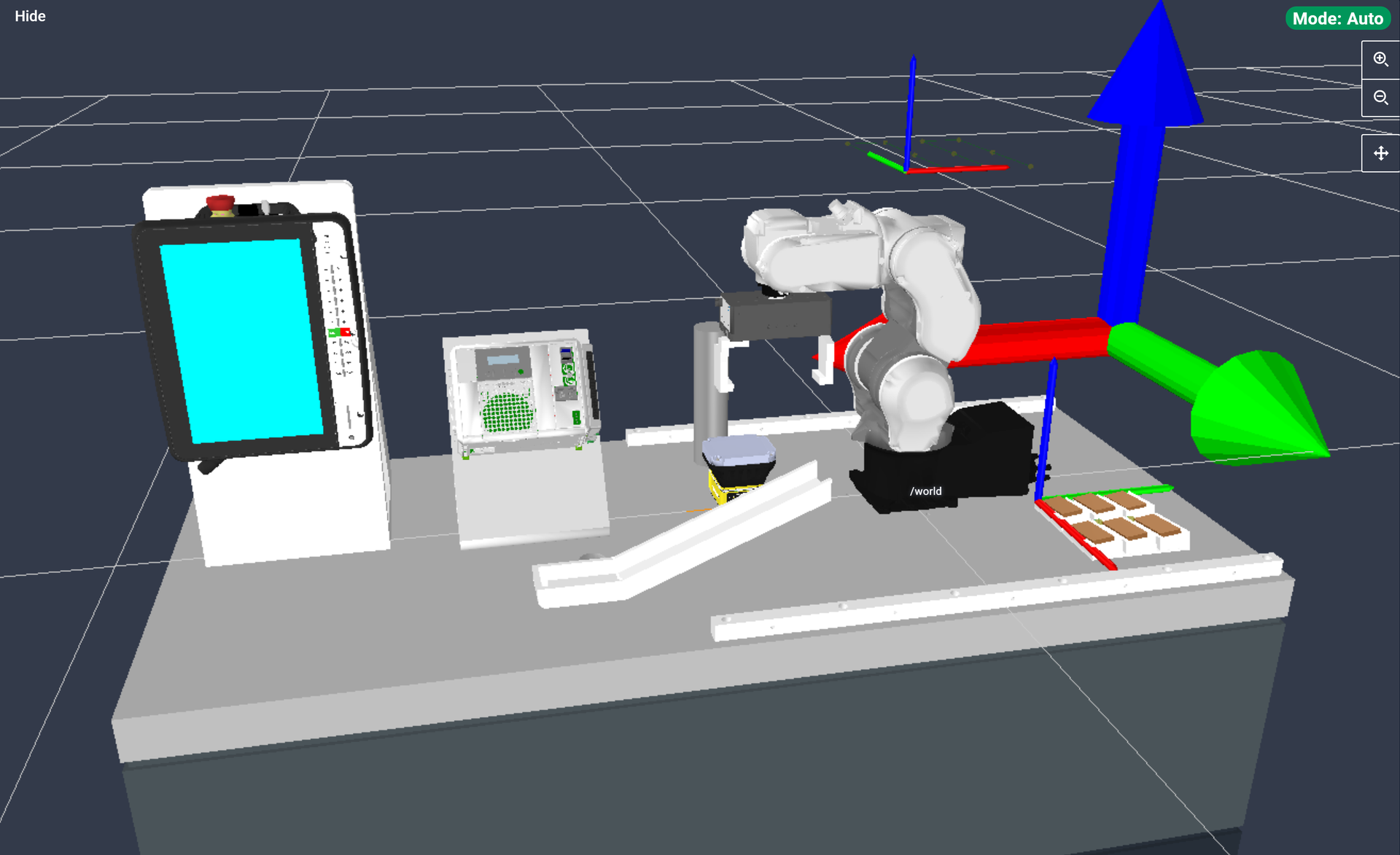

One system: Kemro X

Machine control, robotics, proprietary software, safety, visualization in one system reduce hardware costs, complexity and effort.

Robot programming

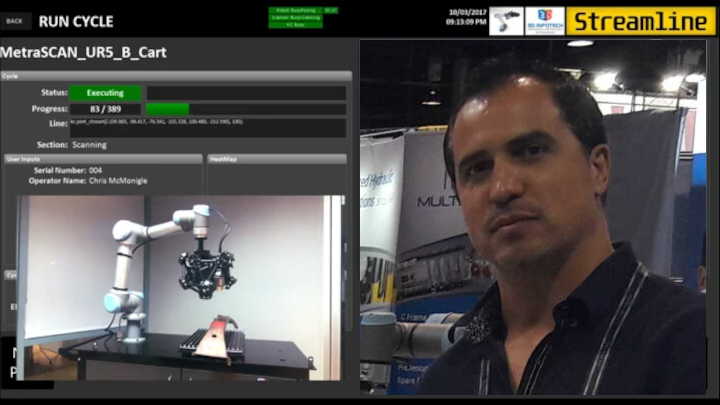

Classic versus drag&bot OS

In contrast to conventional robot programming with the teach pendant of the robot, operation with drag&bot OS is not only much easier and faster, but also more uniform.

You only need one software to operate all your robots.

Typical applications

Machine loading, Flexible Standard Cells and Robot Builders are the most common applications of drag&bot OS.

Machine feeding

The robot-assisted, integrated loading and unloading of machines offers machine manufacturers new opportunities to meaningfully expand their range around their core products. End users thus receive machine and automation from a single source.

With drag&bot OS, machine manufacturers get a ready-made solution for integrating robots from different manufacturers in conjunction with visualization for easy operation and customization by the end user. White-labeling and customer-specific extensions are possible without much effort.

Flexible robot cell

Flexible robot cells offer a cost-effective option for retrofitting robot automation in existing machinery. Thanks to the movable platform and intuitive operation, commissioning and changeover times are reduced, while the robot is always used exactly where it is needed.

drag&bot OS offers an easy-to-use, no-code user interface and works with ABB, Fanuc, KUKA, Yaskawa, etc.

Robot manufacturer

Manufacturers of process-specific industrial and collaborative robots need an integrated user interface such as drag&bot OS so that their end users can use their systems without time-consuming training and cumbersome line-by-line programming.

drag&bot OS – together with the robot controller KeMotion – offers a basic solution for intuitive and individually adaptable, graphical visualization and operation for robots with special tasks.

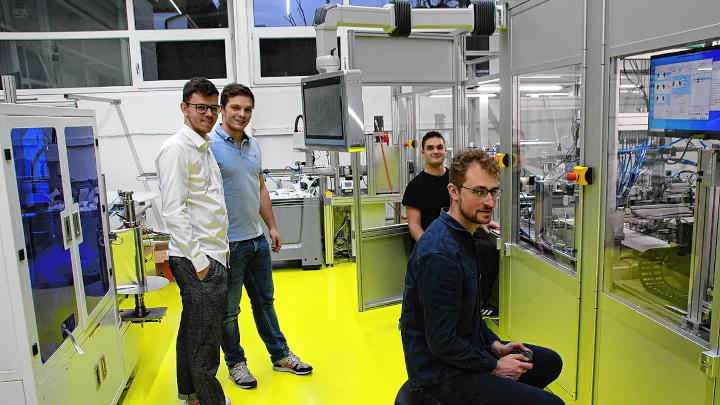

ZiMo - flexible robot cell

ZiMo, a mobile robot cell from the Zimmer Group, is suitable for process automation, for example for assembly, loading and unloading machines, pick-and-place or training purposes - especially for smaller and changing batch sizes. The cell makes it easy to get started with robot automation.

- Simple operation without programming knowledge: The robot and end effector are controlled via an integrated control panel with intuitive software.

- Time and resource savings: The flexible

robot cell can be set up and commissioned intuitively via the HMI, saving valuable time and resources. - Fast integration into existing processes: Rapid integration into existing processes minimizes downtime and facilitates the transition to automation without costly restructuring.

- Increase in quality: Whether semi-automated human-cobot collaborations or fully automated production, ZiMo offers faster cycle times and increases quality as well as productivity.

- Fast ROI: Rapid adaptation to individual customer requirements enables short set-up times, so that even small batches can be automated economically.